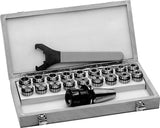

ER Collets

ER Collet: Precision Clamping for CNC Machining

Discover the reliability of ER collets, precision clamping devices designed for CNC machining centers, lathes, and milling machines. Part of the ER (Elastic Reamed) collet system, these tools offer unmatched versatility and accuracy, which is ideal for industrial applications and precision hobbyist projects.

Why Choose Premium ER Collets?

- DIN 6499 / ISO 15488 Compliance: Ensures industry-standard concentricity and easy interchangeability with other tool-holding systems.

- Engineered with High-Grade Spring Steel: These collets are hardened and precision-ground, ensuring long-term durability and exceptional accuracy.

- Double-Slitted 1:16 Taper Design: Delivers consistent gripping force and even clamping pressure, crucial for precision machining tasks.

- Wide Clamping Range: Securely holds round shank tools from 1/16" to 1.02" (1.5mm to 26mm), covering a broad spectrum of applications.

- Sealed Versions Available: Ideal for coolant-through setups, improving chip evacuation, and extending tool life.

Long-Term Advantages in Machining:

- High-Speed Precision: Achieve minimal runout and vibration, crucial for superior surface finishes in demanding machining operations.

- Efficient Tool Changeovers: Save time with quick setup and easy tool transitions, enhancing overall productivity.

- Versatile Material Compatibility: These collets easily handle a wide range of materials, from metals to composites.

- Multi-Functional: Perfect for milling, drilling, boring, reaming, and more, ensuring your machining operations are always efficient.

- Broad Compatibility: It works seamlessly with ER collet chucks and tool holding systems from leading manufacturers like Centaur and Rego-Fix.

Why Invest in Premium ER Collets?

Investing in high-quality ER collets from Centaur or Rego-Fix ensures your machining operations run smoothly, offering unmatched precision, repeatability, and longevity. These collets are designed for professionals who demand the best, providing cost-effective solutions that stand the test of time.

Engage with Us: Share your experiences or ask questions in the reviews. Explore our video tutorials and guides for tips on maximizing the performance of your ER collets.

- "Best ER collets for precision CNC machining"

- "High-performance ER collets for high-speed machining"

- "Durable ER collets for metalworking"

- "Industrial-grade ER collets for professional machinists"

- "Precision tool-holding with ER collets"

Hashtags:

#ERCollets #PrecisionMachining #CNC #ToolHolding #HighSpeedMachining #Metalworking #CentaurCollets #RegoFix #MachinistTools #ERSystem #ColletChucks #EngineeringTools #IndustrialTools #Milling #Lathes #Boring #Drilling #HighPrecision #MachiningExcellence